Magnetic Glass

PreMag is our range of magnetic glass wipe boards which are customisable and offered in a range of finishes from standard white, back painted in a colour of your choice or customised with a print or logo.

We can also supply double-sided magnetic glass which can be a mix of painted and printed finishes, perfect for use in partitions or wall dividers.

Key benefits:

• The glass surface will not degrade or discolour like traditional whiteboards. Glass is non-porous, easy to maintain and hygienic.

• Perfect for writing on using dry wipe or chalk pens, or use as a magnetic memo board.

• Two options for fitting, hidden or exposed fittings are available.

• Our experienced team will assist you to ensure you get the right product and your questions answered.

• Made from 4mm low iron toughened safety glass to ensure clarity of the chosen paint colour, all edges are polished, and any fixings or cut outs for sockets can be catered for during the manufacturing process, prior to the magnetically receptive backing being adhered.

• Made in Britain accredited.

• Peace of mind with two-year warranty against discolouration or delamination (subject to Terms and Conditions).

Ideas for use:

PreMag magnetic wipe boards can be utilised in a variety of ways from a simple wipe board for writing or to hold paper or material as memo type board, to more bespoke wipe boards used as a task planner, restaurant menu, notice board, work wall or partitioning. They can be found in meeting rooms, at information points, student halls, office interiors etc.

Technical details:

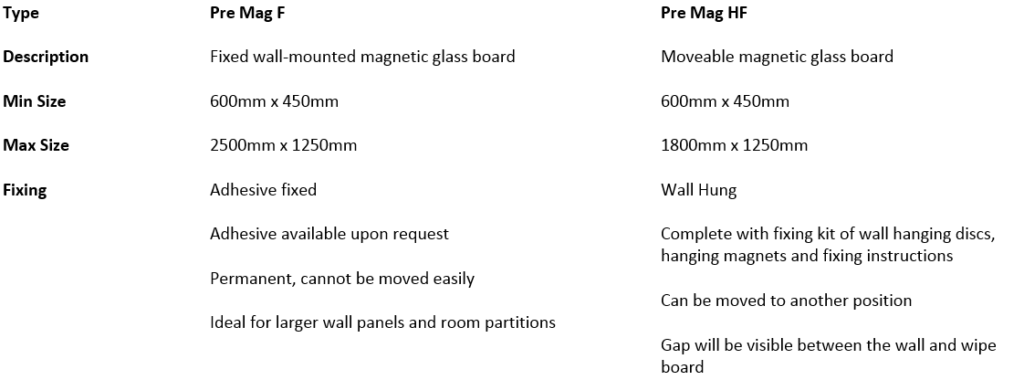

Differences between fixed (permanent) and hidden fixings (movable)

Magnetic glass wipe boards are for internal use only.

The board is packed for delivery, loose loaded with travelling spacer pads, with optional extras of foam edge or corner protectors.

Weight per board is approximately 15kgs per m2.

Accessories such as magnets are available upon request.

Please take into consideration the substrate weight limit as well as the lighting as this can change the visual effect of the colour.

All our products are backed by a full quality control process, a paint library, and for bespoke projects, control samples to ensure the whole project from first to last panel are consistent in colour shade and quality.

Colour and finishes

Available in white, a variety of colours, sparkle or metallic finishes.

Colour matching is available upon request.

You can customise your magnetic glass wipe board using our Atoll Marbled or other collections, your own text, images or patterns.

Please ensure that you have the licence to reproduce or are using a licence free image.

Printing artwork

Image / Photo / Bitmap – please supply in the size ready to print and in the following formats

- 300 dpi minimum

- CMYK

- .tiff or .psd

Graphics / Vector Graphics – imagine should be to size and without manipulation needed. Please specify if cut outs etc. are required and where. Please supply in the following formats

- CMYK

- .eps or .ai

Installation

Preedy Glass offer a survey, site, and installation service for both the fixed and hidden fixings options. Our contracts department are experienced in working with site schedules and call off orders to ensure installations run smoothly on time and to budget.

Safety and standards

Resistant to EN12600 class 1B1 and breakage mode C.

Toughened to EN12150.

Metal backing to standard BS EN10346 DX51D.

As a member of the Glass and Glazing Federation, we adhere to their visual quality standards and comply with the GGF Consumer Code of Practice.

Cleaning and aftercare

PreMag can be cleaned with a standard dry wipe eraser to remove dry wipe pens, and wet cleaned on the front face of the glass to remove a chalk marker.

Glass can be washed with plenty of clean water, sometimes adding a small amount of mild, neutral detergent or a domestic or commercial glass cleaner, if cleaning the front face. Use either a new soft paper wipe or a new lint free cloth. To avoid scratching the glass surface, no abrasive materials should be use.

Take care to avoid any cleaning product damaging the painted side of the glass.

Any spillages or stains are to be cleaned off immediately to avoid permanent damage to the glass.

Lead times

Production time is normally 10-15 working days, or for customised versions 15-20 days upon receipt of final specification and artwork. For large volumes, lead time will be advised at the estimate stage.